SuperCooler™

News ⋅ SuperCooler™ ⋅ July 30, 2025

Solving the Scale-Up Challenge: Introducing ECI Group’s High Pressure SuperCooler™

At ECI Group, we’ve always been at the forefront of innovation in high-pressure polyethylene (HPPE) technology. As the global demand for polyethylene continues to grow, so does the need for efficient, scalable, and cost-effective production solutions. That’s why we’re proud to introduce our latest breakthrough: the High Pressure SuperCooler™.

Who We Are

ECI Group is a global leader in HPPE technology and engineering solutions. Since 2021, we’re licensed eight new LDPE/EVA trains utilising our proprietary Hybrid HPPE technology, ranging from 50 KTA to 200 KTA, and now offer capacities up to 500 KTA. Our expertise spans the full plant lifecycle—from R&D and engineering to commissioning and operational support.

The Scale-Up Challenge: Heat Exchange vs. Pressure Drop

As polyethylene plants scale up, they face a paradox: increased gas flow demands larger reactor tubes, which in turn reduces heat transfer efficiency and increases pressure drop. This leads to:

- Higher compression costs

- Larger ethylene inventory

- Bigger reactor bays

- Increased capital and operating expenses

Enter the SuperCooler™

ECI Group’s SuperCooler™ is a patent-pending high-pressure heat exchanger that solves this paradox. Compared to standard double pipe modules, it offers:

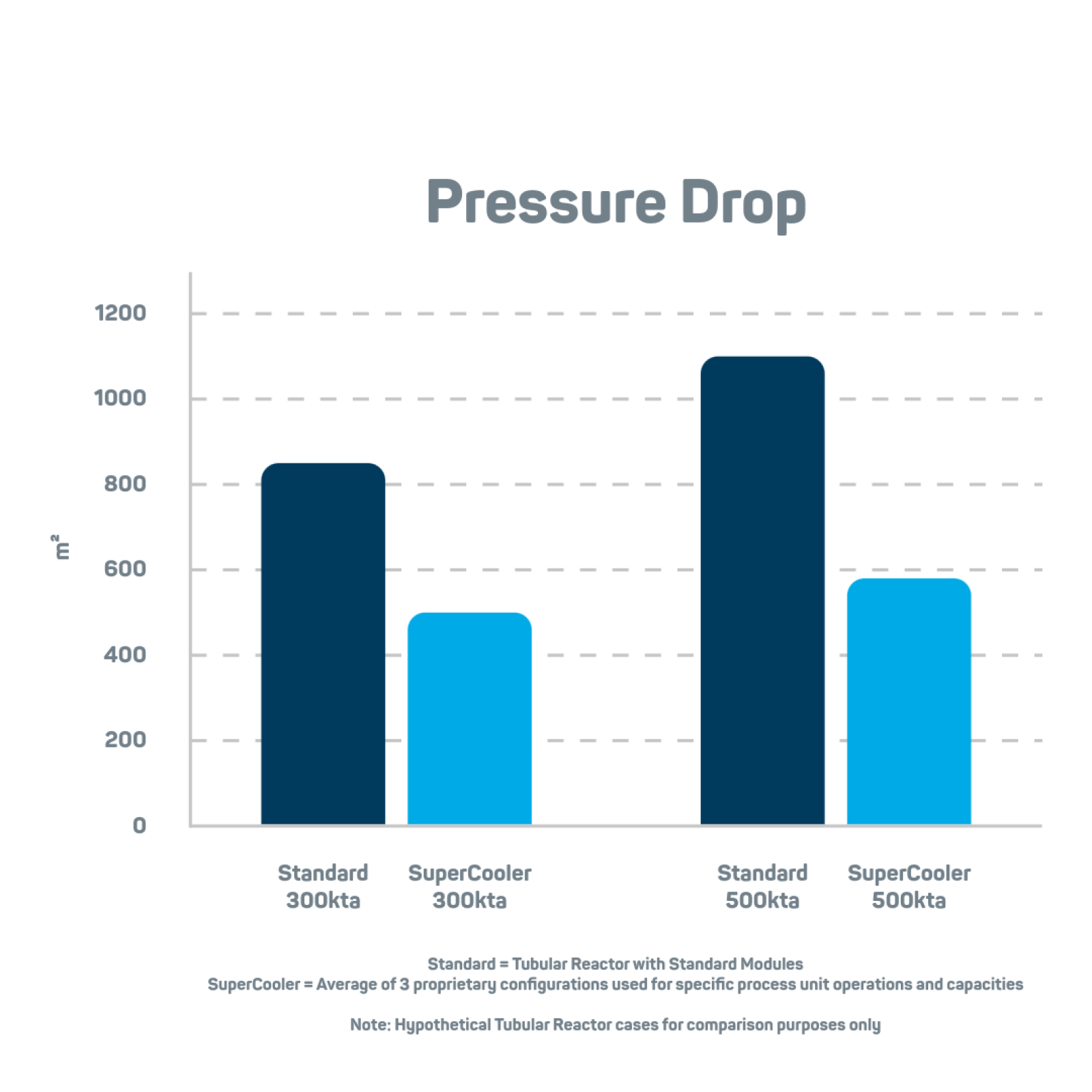

- Significantly reduced pressure drop → Lower energy consumption

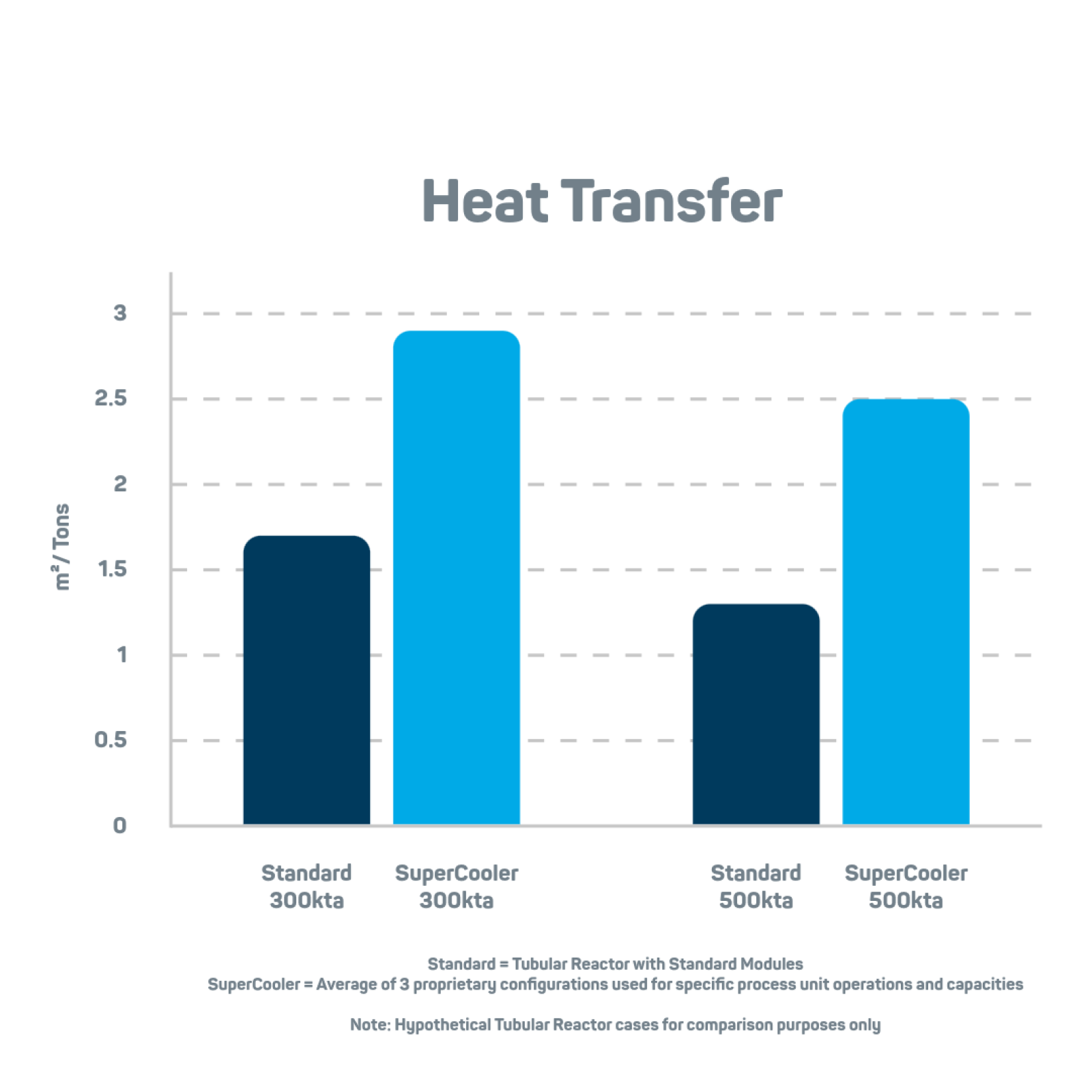

- Enhanced heat transfer effectiveness → Shorter reactor tubes

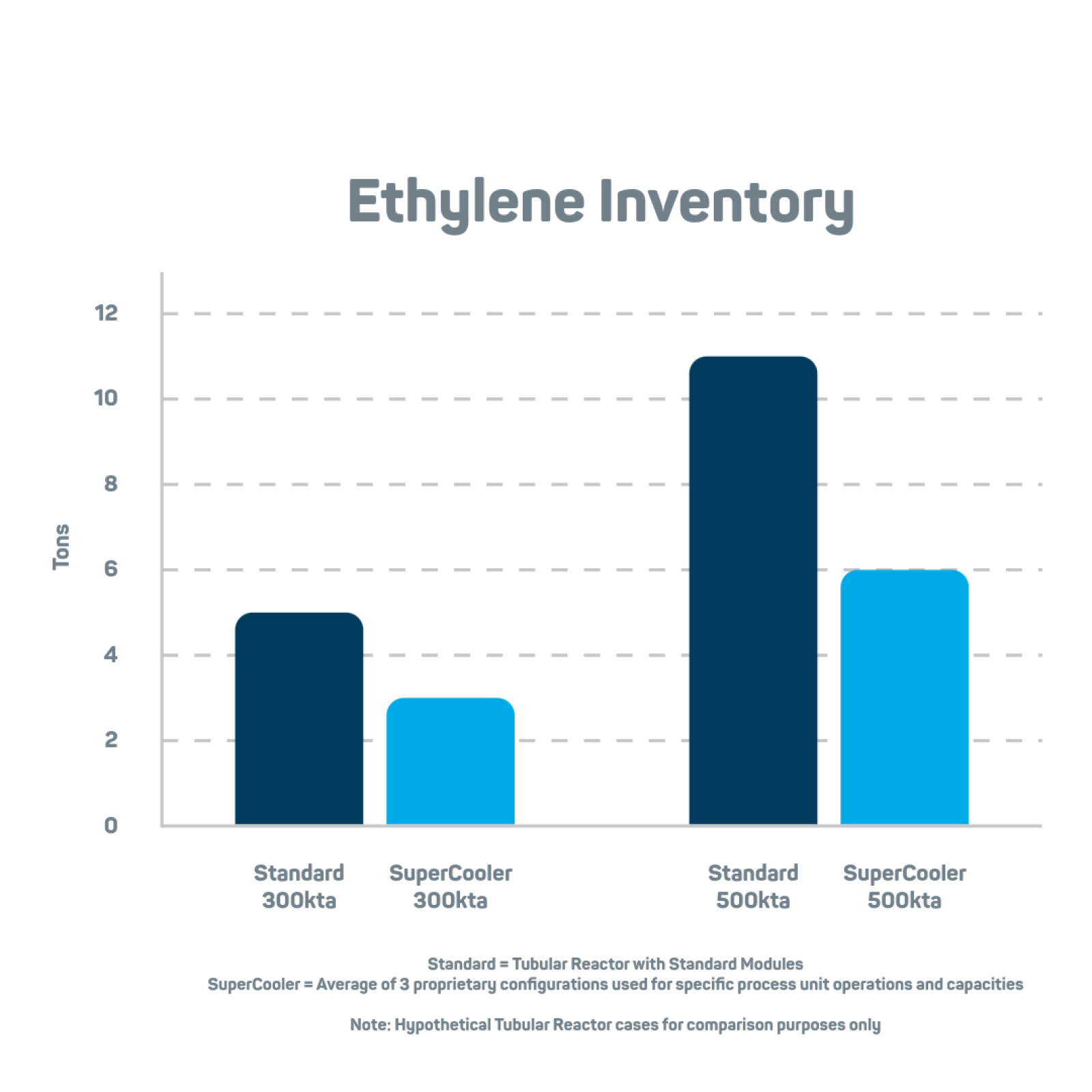

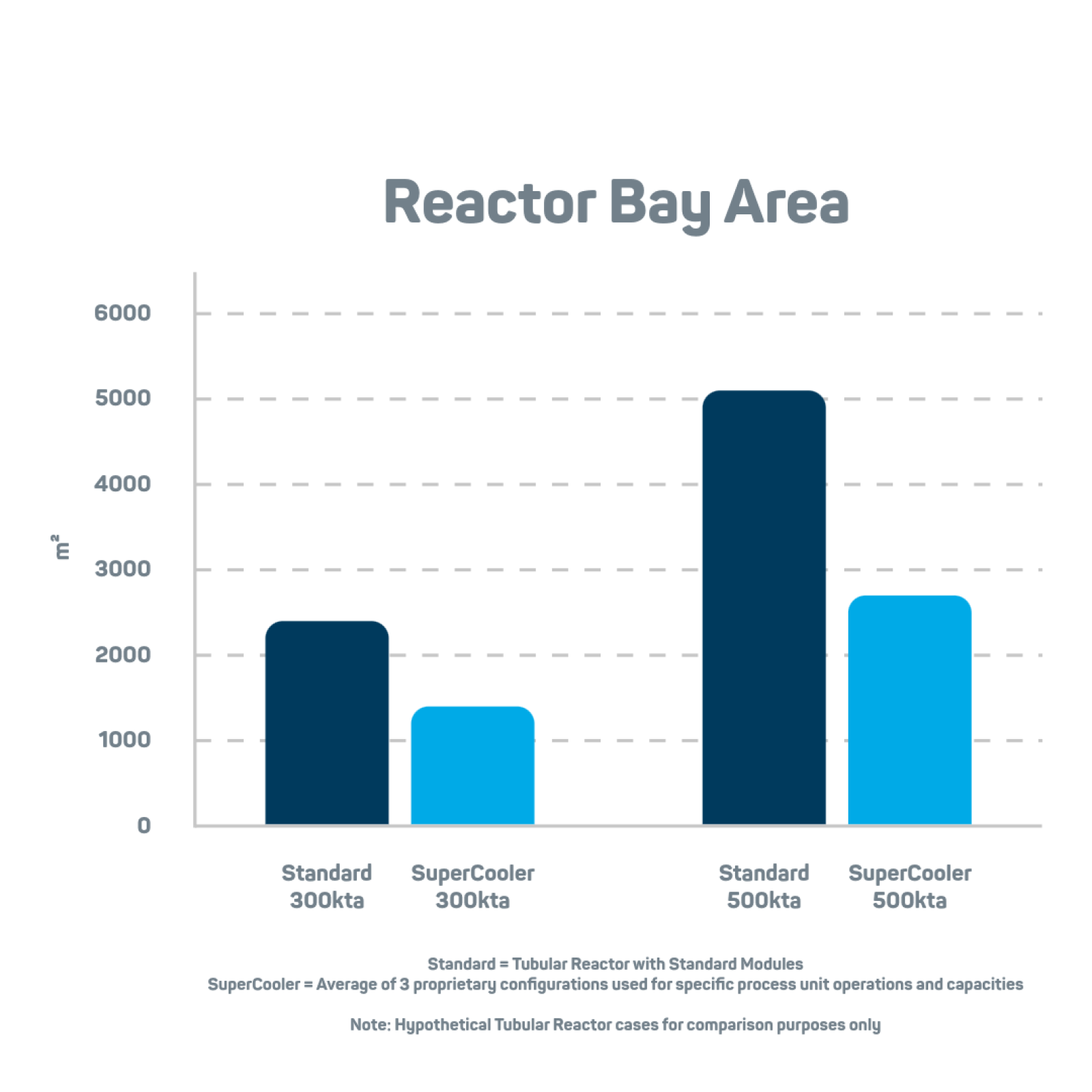

- Reduced ethylene inventory → Smaller reactor bay footprint

- Lower capital and operating costs

Real-World Impact: Hypothetical Case Studies

In simulated comparisons:

- Pressure drop was almost halved

- Heat transfer effectiveness tripled

- Ethylene inventory dropped by 50%

- Reactor bay area shrank by 50%

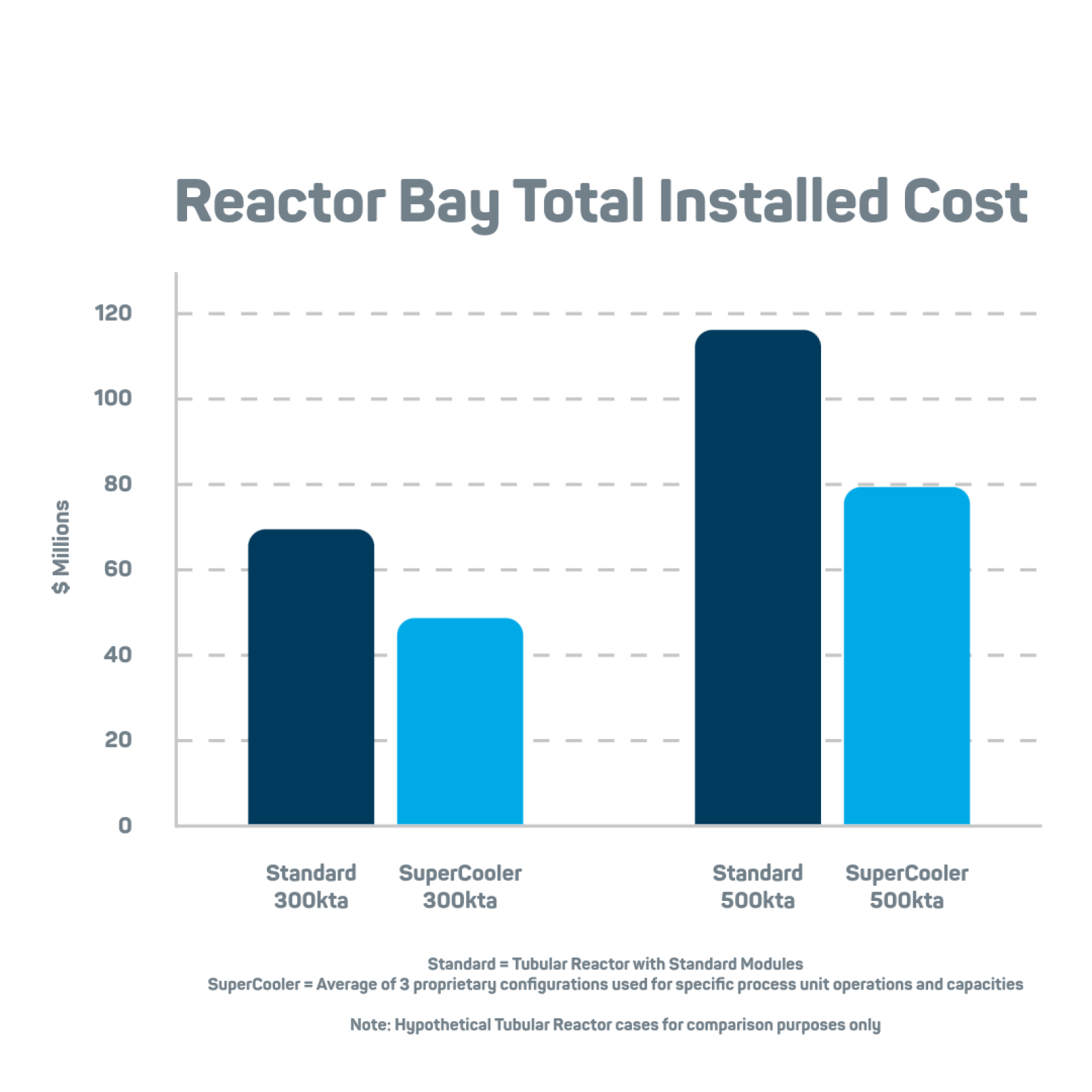

- Reactor bay total installed cost (TIC) savings exceeded $35 million

Versatile Applications

The SuperCooler™ is ready to be integrated into all of ECI Group’s high-capacity lines (300–500 KTA) and is suitable for:

- Intercoolers

- Feed gas coolers

- Pre-heaters and pre-coolers

- Reactor cooling zones

- Product and after-coolers

Its modular design also simplifies maintenance, reduces spare parts inventory, and supports assembly-line fabrication.

The SuperCooler™ can be adapted for both new build projects and existing operating plants.

Flexibility for the Future

ECI Group’s technology is built for product and capacity flexibility. Our lines can produce a wide range of polymers and copolymers—including LDPE, EVA, and ENBA—within a single configuration. With scalable designs from 50 KTA to 500 KTA, ECI Group ensures our clients can grow and adapt with market demands.

The Future of HPPE

At ECI Group, we believe that innovation should deliver measurable value. The High Pressure SuperCooler™ is more than a technological advancement—it’s a strategic solution that empowers our clients to scale efficiently, reduce costs, and stay competitive in a dynamic market.

Talk to us to discover how the SuperCooler™ can add benefits to your plant.

Let’s engineer the future of polyethylene—together.

Chris Brock, ECI Group’s Director of High Pressure Polyethylene Business Technology Unit, introduced the SuperCooler™ during his presentation at the 18th LDPE Plant Improvement Conference.