The facility, to be built in Antwerp, Belgium, represents a pivotal step in the transition to sustainable plastics. It will use ECI Group’s proprietary autoclave technology to produce 110,000 tonnes of LDPE per year from certified green methanol. The venture is backed by A.P. Moller, with ECI Group’s product partner, Repsol, providing essential market knowledge and product expertise.

ECI Group’s President and CEO, Joaquin Flores, commented, “We’re proud to have been selected to support Vioneo’s vision to create the world’s first green LDPE plant and the first new autoclave LDPE plant to be built in Europe in forty years. This project aligns perfectly with our vision of providing technology solutions that drive sustainable innovation.”

Vioneo, backed by A.P. Moller Holding, is dedicated to pioneering fossil-free plastics production. The plant will form part of the Vioneo’s planned production complex in Antwerp, Belgium which aims to address fundamental environmental challenges associated with conventional plastics manufacturing and will position Europe at the forefront of the transition to a sustainable ‘fossil-free’ plastics industry.

“Vioneo is driving the transition of the plastics industry by demonstrating the economic viability of large-scale, cleaner production using green methanol instead of fossil fuels. This initiative offers Europe the opportunity to lead the €5 trillion chemicals and materials sector’s defossilisation. Our partnership with ECI Group is a crucial step in realising this vision,” said Alex Hogan, Chief Executive Officer, Vioneo.

The LDPE plant will use a green methanol feedstock derived from biogenic CO₂, ensuring a fully fossil-free, traceable, and ISCC PLUS-certified product. Powered by renewable electricity, the facility will significantly reduce lifecycle emissions while delivering high-performance LDPE suitable for critical applications in healthcare, automotive, packaging, and consumer goods.

“This project is a landmark moment for the polymer industry. By combining green methanol with our high-pressure polyethylene technology, we’re enabling a truly fossil-free approach to plastics manufacturing. We look forward to working with Vioneo to deliver this first-of-its-kind facility,” said ECI Group’s Director for HPPE Technology, Chris Brock.

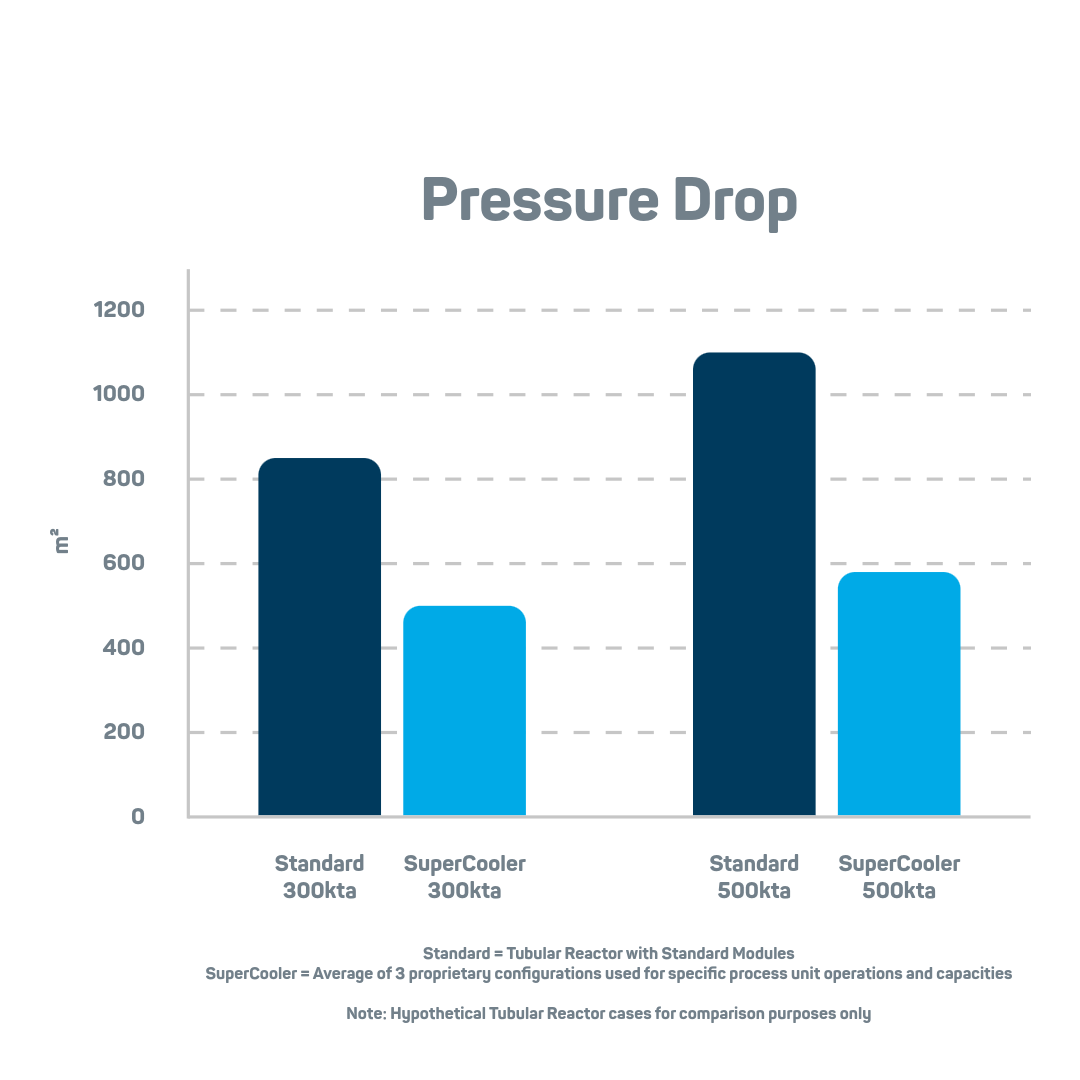

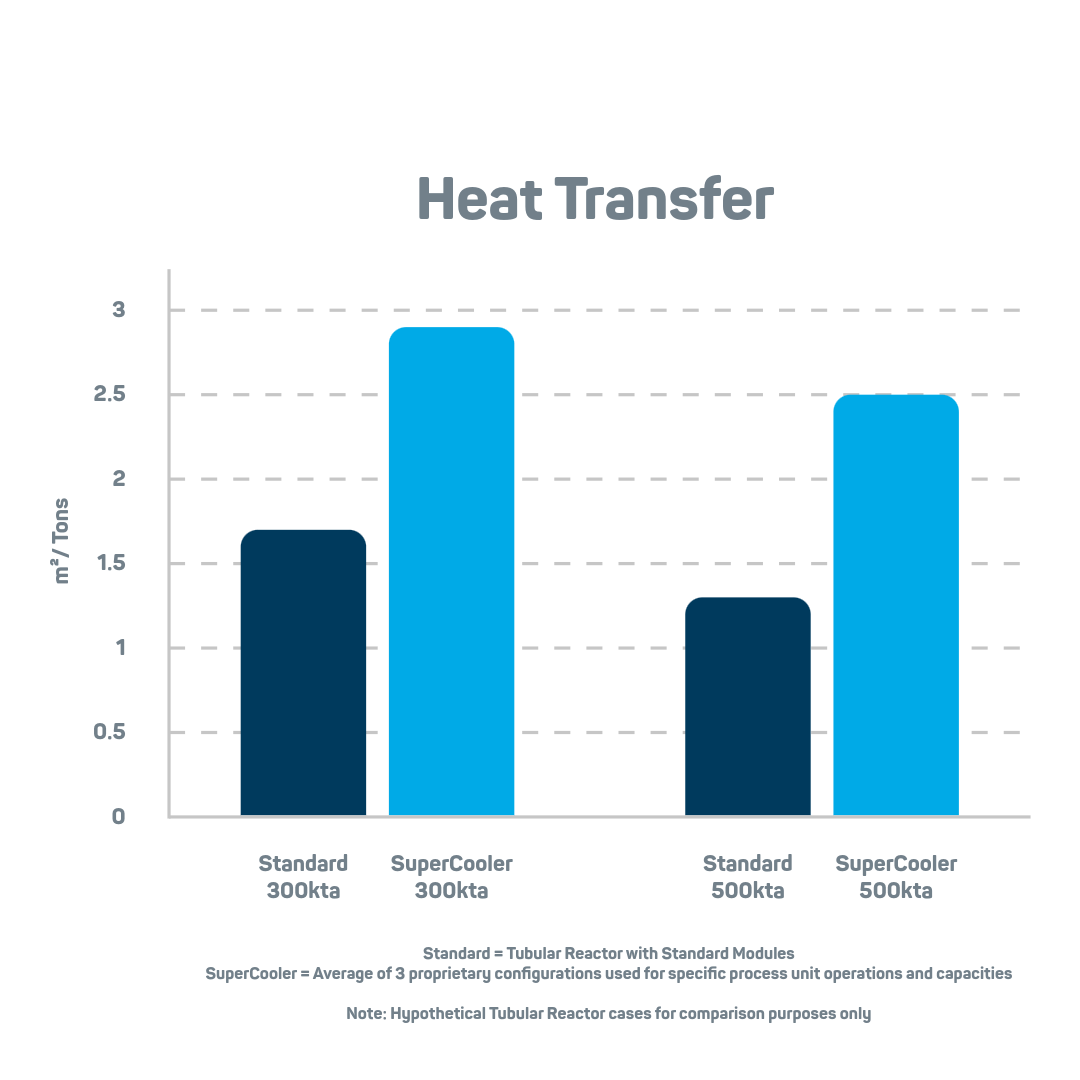

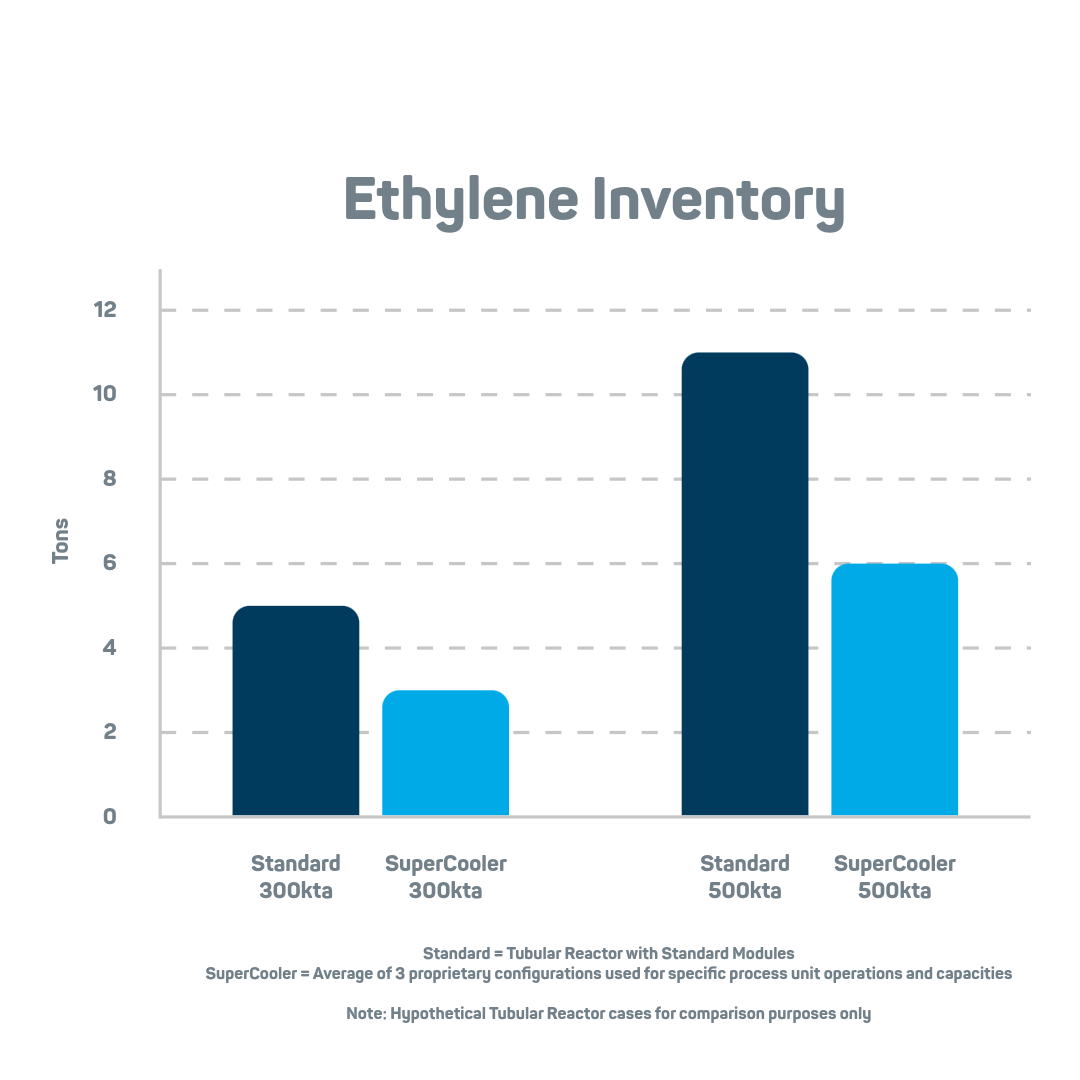

ECI Group’s proprietary technology offers a wide range of high-pressure polyethylene products, providing unrivalled operational efficiency, reliability, and flexibility. Building on ECI Group’s decades of experience within the polymer industry, their technology has been optimized to make use of modern materials, design techniques, standards, and industry best practices for construction, operation, and maintenance. In the four years since 2021, ECI Group has licensed over one million tonnes of annual capacity, all using ECI Group’s standardised design approach.

Repsol, the multi-energy company, will support ECI Group as product partner, bringing its extensive technical, operational, and commercial expertise. Repsol has over 55 years of experience producing LDPE, EVA, and EBA polymers at its industrial complexes in Spain and Portugal.

About ECI Group

ECI Group comprises Engineers and Constructors International, Inc., headquartered in Baton Rouge, Louisiana, and Simon Carves Engineering Ltd., headquartered in Manchester, UK, as well as the International Technical Excellence Center (ITEC). With its history stretching back nearly 150 years to the formation of Simon Carves in 1878, ECI Group provides world-leading technology and engineering solutions for polyolefins around the world, offering proprietary technology solutions and multi-discipline engineering services that cover the full lifecycle of the project and the operating plant.

Learn more about our HPPE technology here: www.ecigrouponline.com/polymers.