ECI Group is pleased to announce it has signed a licensing agreement with Shaanxi Yanchang China Coal Yulin Energy & Chemical Co., Ltd. (YECC) to deliver a 150kta copolymer plant project using ECI Group’s proprietary hybrid reactor technology.

YECC is part of the Part of the Shaanxi Yanchang Petroleum Group, China’s fourth largest oil producer with significant petrochemical production facilities based in Shaanxi, Northwestern China. The plant will be located in Yangqiaopan, Jingbian County, Yulin City, Shaanxi Province. ECI Group’s technology will enable the plant to produce 150,000 tonnes per year of LDPE, EVA, EBA and other high-value copolymer products, with the ability for future expansion of both capacity and product capability.

ECI Group will provide the technology license, process design package, expanded process design package, and detailed design for the high-pressure system as well as technical procurement services for the project and on-site technical support during installation, start-up, and performance assessment. ECI Group will be supported by Repsol who will provide extensive technical, operational, and commercial expertise. Repsol has over 40 years of experience producing LDPE, EVA, and EBA polymer products in its industrial complexes in Spain and Portugal.

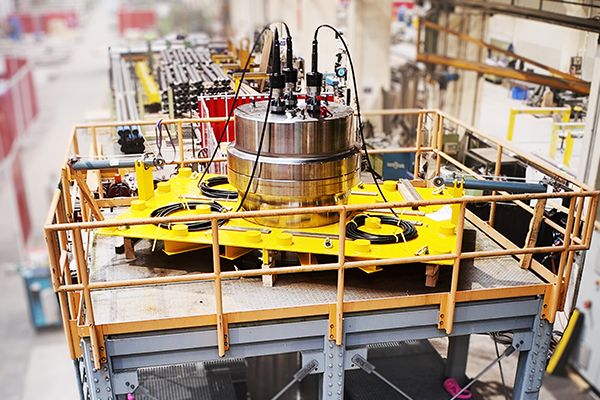

ECI Group’s hybrid reactor technology has been developed from the well-proven ICI autoclave technology and offers a wide range of high-pressure polyethylene products, providing unrivalled operational efficiency, reliability, and flexibility. ECI Group’s hybrid reactor technology offers significant improvements in the product range, reliability, and expandability to the original ICI technology, and has been optimized to make use of modern materials, design techniques, standards, and industry best practices for construction, operation, and maintenance. Since 2021, ECI Group has licensed plant capacities of 50kta, 100kta, 150kta and 200kta, all using ECI Group’s standardised design approach. This licensing agreement with YECC demonstrates the reputation and versatility of ECI Group’s hybrid reactor technology.

Joaquin Flores, ECI Group’s President and CEO, said:

“ We are delighted that a client as esteemed as Shaanxi Yanchang China Coal Yulin Energy & Chemical Company has chosen ECI Group’s technology after a competitive tendering process and we look forward to successfully delivering this project for them.”

Chris Brock, ECI Group’s Business and Technology Director – HPPE, said:

“ ECI Group’s hybrid technology represents a modern approach to high-pressure polyethylene plant design, providing the best combination of production and reliability while providing a superior product range. It’s a game-changer for the industry, allowing clients to access a flexible slate of high-value products at world scale capacities. We’re excited to bring our offering to more clients around the world.”